3 inch stainless steel exhaust pipe 90 degree elbow 3 inch stainless steel 90 degree elbow 90 degree elbow steel

Product ID : 01

Product Attributes :

Place of Origin

Hebei, China

Customized support

OEM

Brand Name

YJD

Model Number

1.5"-110"

Connection

Welding

Connection

Welding

material

Stainless steel

Type

Connection

Color

Stainless steel Plain

Material

Stainless steel 304

Certification

ISO9001:2015

Surface

Polishing

Thread

No thread

Product Description

|

3 inch stainless steel exhaust pipe 90 degree elbow

|

|

|

Car model

|

Universal

|

|

Material

|

304 Stainless Steel

201 Stainless Steel 409 Stainless Steel Titanium Aluminum Accept customized |

|

Exhaust type

|

Exhaust Elbow

90 Degrees Pipe

|

|

Pipe Diameter

|

ID/OD:2''/2.25/2.5''/3''

Accept size customized |

|

Thickness

|

1.0mm-72mm

Accept customized |

|

Bend Degree

|

45° 90°

Accept customized |

|

Quality

|

High Quality

|

|

Surface

|

Mirror Polish

|

|

Color

|

As Picture Showing

|

|

Brand Name

|

YJD

|

|

Place of Origin

|

Hebei,China

|

|

Packing

|

Carton,Pallet or according to requirements

|

|

Installation

|

Plug And Play , In-situ Easy Installation

|

Due to the fact that most pipe fittings are used for welding, in order to improve welding quality, the ends are turned into grooves with a certain angle and edges.

This requirement is also quite strict, with regulations on the thickness of the edges, the angle and deviation range. The surface quality and mechanical properties are basically the same as those of pipes.

For the convenience of welding, the steel grade of the pipe fittings and the connected pipes is the same.

All pipe fittings must undergo surface treatment, and the oxide scale on the inner and outer surfaces should be shot blasted off before being coated with anti-corrosion paint

The packaging requirements for small pipe fittings, such as exports, require a wooden box of approximately 1 cubic meter.

It is stipulated that the number of elbows in this box cannot exceed one ton. This standard allows for a set, that is, a large set with a small set, but the total weight generally cannot exceed one ton.

For large items, they must be individually packaged, and for items like 24 inches,

they must be individually packaged. Another thing is packaging marking, which should indicate size, steel grade, batch number, manufacturer's trademark, etc.

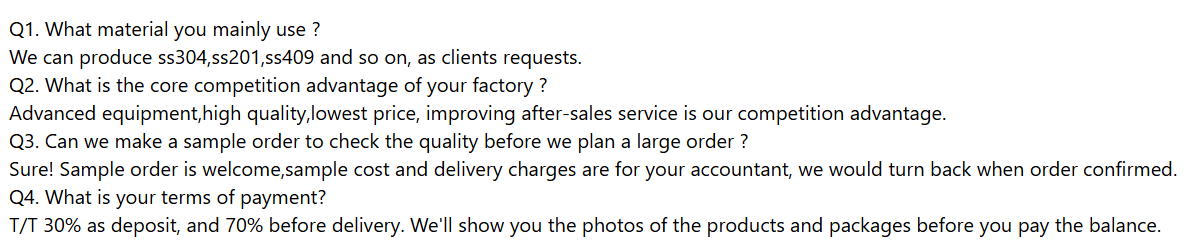

FAQ

Online Inquiry